Best Drone Motors: 4 Things You Must Know While Choosing The Correct Power Source For Flight Leave a comment

Even the most potent drones remain grounded in the absence of their motor. The latter is the sole component that supplies power lift and maneuverability. There are various types of drone motors, and choosing appropriately is important for effective application.

With applications in aerial photography, field study, research, development, and even military operations, drone failure causes project failure. A wrong motor makes it difficult for the drone to lift weight, causing poor flight performance and even unsuccessful operations.

Hence, to avoid the wrong motor consequences like noise, increased operational time, instability, and lack of control, choosing the correct type is essential.

So, without any further ado, let’s dig into the details!

Working Of A Drone Motor

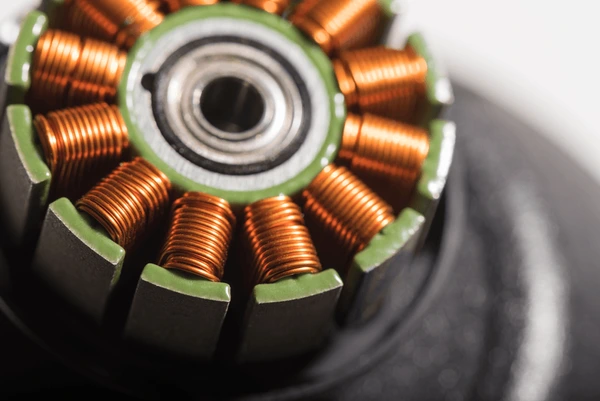

Both the major types of motors, viz Brushless and Brushed, uses electromagnetism to run the motor. This specified that these function as electromagnets in their design. So, when the electromagnet develops charge, it surrounds itself with a magnetic field.

Though the magnetic field is temporary, it comes in contact with the permanent magnets. Next, both generate attractive and repulsive forces of electromagnetism and even permanent magnets. These forces in cohesion rotate the motor shaft by converting electrical energy to kinetic energy throughout its working.

What Are Different Types Of Drone Motors?

As mentioned above, the two types of Drone motors differ in efficiency, structure, and applications.

Brushless Motors

As the name suggests, these are drone motors without any brushes. The latter is an asset as there’s a lesser chance of wear and tear; thus, they are long-term durable. They provide better performance in terms of power as well.

Managing the electric flow without brushes would seem complicated, but it has a regulated flow. Without any negative impact, Brushless motors provide smooth output. Since it is Brushless, it is lightweight compared to brushed motors and emits heat. It is another reason these motors stay viable for a long time.

Owing to the lesser weight, it consumes less power. Consequently, it delivers better output, which makes the motor suitable for high-performance drones and finds applications in contemporary models.

Pros

- Make lesser noise as compared to brushed motors

- Highly efficient throughout its working

- Lesser overheating of internal components

Cons

- Complex functionality

- Expensive

Brushed Motors

Brushed drone motors, as the name suggests, have brushes present in them. They mostly find their applications in amateurish and low-scalability drones for simple functionality. It has a spinning structure that surrounds the magnet.

However, they have low power efficiency at high speeds and suffer from wear and tear. Also, after a long hour of usage, these drones overheat.

Pros

- Beginner-friendly design

- Suitable for small drones

- Cost-effective

Cons

- Noisier due to brushes

- Not much durable

Coreless Motors Brushed DC Motors

Coreless drone motors are a subtype of Brushed DC motors that don’t have an iron core surrounding the spinner. To cope with its absence, it uses a wired coil near its center.

Yet, owing to this, it is more lightweight than most brushed motors and hence has better speed. However, it has its applications only in tinier and toy drones.

Drone Motor Configurations

Apart from the type of drone motors, even the motor configuration matters when depending upon the application. Accordingly, there are different drone motor configurations, often mistaken as types.

Single Motor Configuration

The drones which use only one motor for all of their functionalities and can do so without any risk have a single Motor configuration.

Depending upon its design, it has two types:

- Coaxial Designed Single Motor

The motor where all the rotors are arranged one over the other like a stack is known as a Coaxial Design. Yet, all of them have a common axis and rotate in a direction opposite to each other.

Coaxial single motors find application in smaller drones due to their simple application and compact size. Aerial photographers and drone engineers use this motor for beginner-friendly projects.

- Quadcopter Designed Single Motor

As the name suggests, Quadcopter designed single Motor has four rotors arranged in a square pattern. Thus, it has four pairs, of which each part is the couplet spins in the opposite direction.

Moreover, these are stable, easy to control, and find applications in videography and racing.

Multi-Motor Configuration

Drones which use more than one motor for fundamental operations, stability, and for greater lifts are known as multi-motor configurations.

- Hexacopter Design

Hexacopter Design refers to six rotors configured in a hexagonal layout. It consists of three pairs of rotors whose components spin in opposite directions.

Moreover, these are more stable and, hence, can handle greater loads. Even for exceptionally professional purposes like field study, you can use drones with a hexacopter design.

- Octocopter Design

Octocopter design consists of eight rotors arranged in a square or circular pattern. It has four pairs of rotors, of which each couple member spins in an impolite direction.

Further, they have their application in heavy-load operations. It includes cargo transportation, search, and industrial inspections as well. Also, the eight rotors help its drones to travel over longer distances.

Thus, it is ideal for agricultural activities, military missions, mapping, etc.

How To Choose The Correct Drone Motor?

Choosing the appropriate one is quite essential while engineering a drone. There are many factors to consider before deciding, yet some are always underrated but become a significant obstruction.

Minimum Thrust Required

Thrust plays a crucial role in the lift activities of drones. Hence, the minimum thrust should be twice that of the drone weight. For instance, if you have a 500g drone, the motor should provide at least 1kg of thrust.

Thust-To-Weight Ration

Always aim for a higher trust-to-weight ratio so your drone travels faster, like for drone racing and related speedy activities.

Weather, Dust, and Surroundings Prevention

Always ensure that the drone motor stays protected from odd environmental conditions. This includes that motors should have a special design and mechanism to protect them against rain, sun, dust, and corrosion.

Further, top motors often have an internal sealing. It even includes waterproof sealants to cover the bearings and ESCs of the motor. Some even have a protective coating to protect against such conditions and pesticide spray for the safer operation of agricultural drones.

IP Code Specification

Drone Motors have an IP code rating, representing protection against specific components. Therefore, whenever you check motors and ESC components, look for the IP code rating. Accordingly, you should check its IP code proposed to verify that the motor has protection in which situations.

For instance, an IP55 rating suggests that the motor is protected against dust, water sprinklers, and garden hoses.

Most importantly, motor protection against such conditions doesn’t only apply to outdoor drones. Even those you have to run indoors need protection against dust, corrosion, etc.

The Final Word

Whether you are a Drone Pilot, or just want to try flying a drone to explore the facinating gaming world, understanding the correct type of drone motors is important.

Moreover, for complex applications that find their place in the professional sphere, brushless motors work. It’s lightweight, has less noise, durability, and no overheating, which helps it for longer operations.

Yet, it is essential to consider the motor configuration as well when buying or creating one!