BLDC Motor Applications – Everything You Need to Know Leave a comment

Are you wondering what a Brushless DC motor is? What are BLDC motor applications? And why would one choose it over the others? Well, let us help you with all of it. While everyone is trying to flip the pages of a physics book, you can simply tap all the information you need here in this article. Read the entire piece of writing to be well informed.

What is a Brushless DC Motor?

You must have come across the terms DC (Direct Current) motor and AC (Alternating Current) motor in your academic life. These are the basic terms which contain a lot of weight in terms of application. While the AC motor is considered more powerful, the DC motor is preferred over it due to its calibre to control the speed above/below the rated levels.

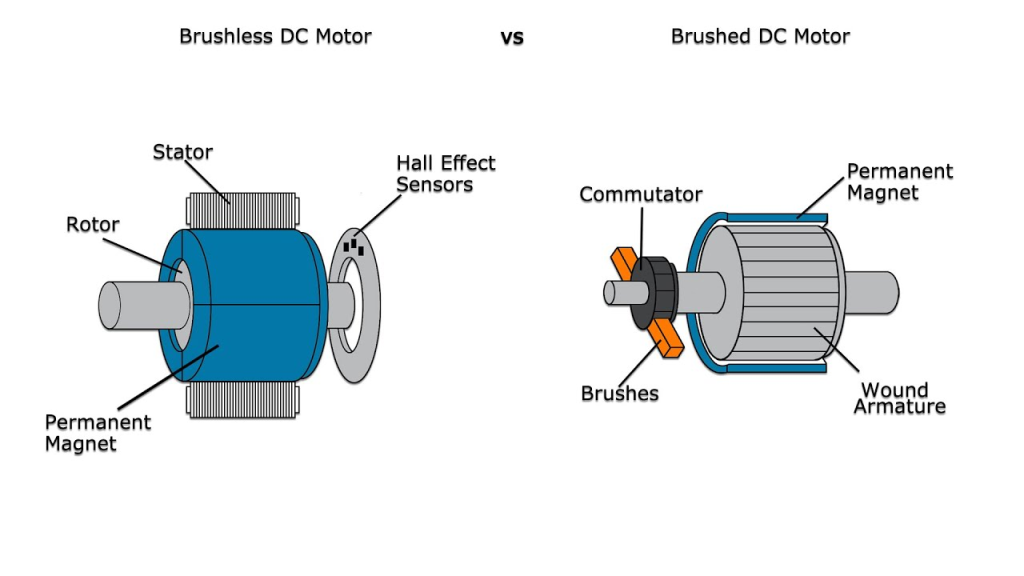

Now comes the Brushless DC motor. BLDC motors are also popular as electronically commutated motors (ECMs). They are widely known for their efficiency and compared to brushed DC motors because in this case, the rotor is the only bearer of magnets. Hence, they don’t require any, meaning no connections and no brushes. Brushes are often replaced with a control circuit.

BLDC motors feature closed-loop control and the pattern they follow requires the driver to always be attentive about the position of the rotor. That is why, these motors employ hall effect sensors, controllers and rotary encoders.

BLDC Motor Applications

When you know how a device or gadget is constructed, it’s easy to understand its features and applications. Now that we have already introduced you to the composition of the BLDC motor, it’s time to take you on a trip to its applications. It is in high demand due to its capability to fulfil the applications requirements such as heavy loads, and constant loads.

These motors are also used for positioning applications in fields like aviation, industrial control, Healthcare, automation, etc. Now, let’s move forward to the thoroughly curated list of the BLDC motor applications.

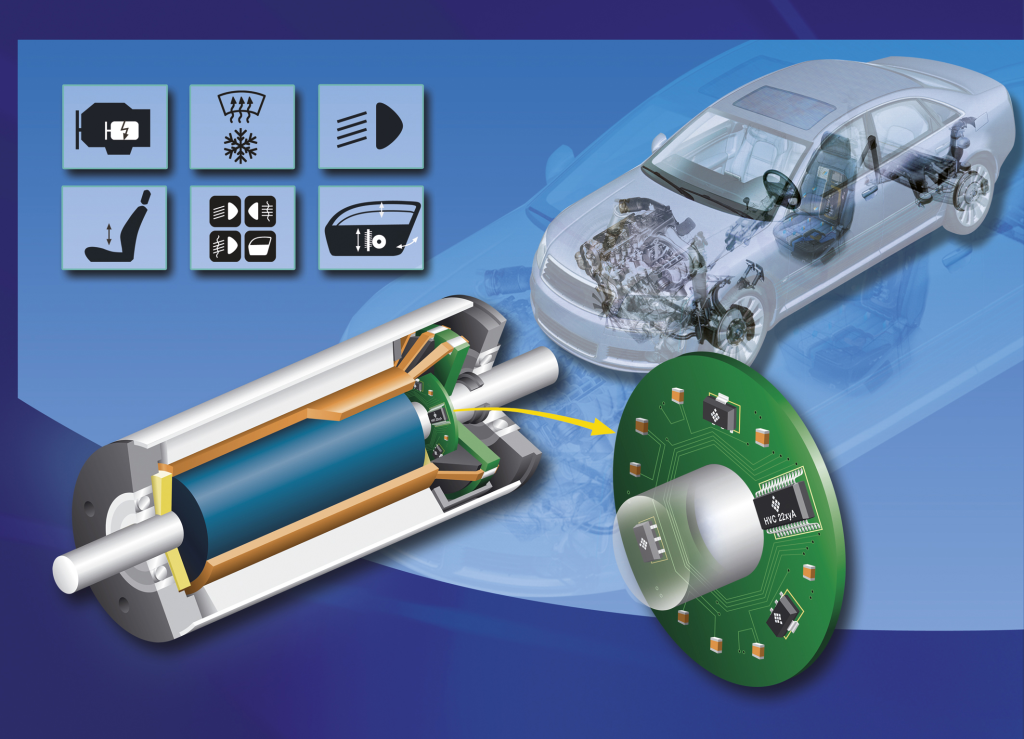

- Consumer Electronics: BLDC motors are extensively used in consumer electronics such as computer hard drives, DVD players, and home appliances like washing machines and air conditioners.

- Transportation: BLDC motors play a crucial role in the transportation sector, especially in electric vehicles (EVs), electric bicycles, and hybrid vehicles. Their high torque-to-weight ratio, superior efficiency, and precise control make them suitable for powering vehicle propulsion systems, ensuring smooth and efficient operation.

- Industrial Machinery: In industrial engineering, BLDC motors are utilised in CNC tools, industrial robots, and automated machinery. Their ability to provide precise control, high-speed operation, and low noise levels make them indispensable in manufacturing processes, improving productivity and reliability.

- Healthcare Equipment: BLDC motors are also used in healthcare equipment such as medical pumps, surgical devices, and diagnostic equipment. Their reliability, low noise output, and precise control contribute to the accuracy and efficiency of medical procedures, ensuring patient safety and comfort.

- Aviation and Aerospace: BLDC motors find applications in aviation and aerospace industries for systems such as actuators, control surfaces, and propulsion systems in unmanned aerial vehicles (UAVs) and drones.

- Heat and Ventilation Systems: BLDC motors are employed in heat and ventilation systems, including compressors, dryers, and fans. Their energy-efficient operation, variable speed control, and long lifespan make them ideal for maintaining optimal indoor climate conditions in residential, commercial, and industrial buildings.

- Packaging Machinery: BLDC motors are integral to packaging equipment such as conveyors, labellers, and sealing machines. Their precise control, high torque capabilities, and reliability ensure smooth and accurate packaging processes, reducing downtime and improving overall efficiency.

- Automated Systems: BLDC motors are used in automated systems and robotics for tasks such as material handling, assembly line operations, and pick-and-place applications.

The lack of brush in DC motors makes them reliable to use upon the requirements of high efficiency and low maintenance. Well, these are the qualities that make these motors stand out in the crowd. I hope you have understood the BLDC motor applications and made up your mind about why to go for this.

What constitutes a Brushless DC motor?

BLDC motor applications are different as its manufacturing process is distinct from the others. In these motors, two permanent magnets are placed on the rotor while the armature or current-carrying conductors are placed on the rotor. They use electrical charges to convert electrical energy to mechanical energy. Let’s have a look at the parts that constitute this motor:

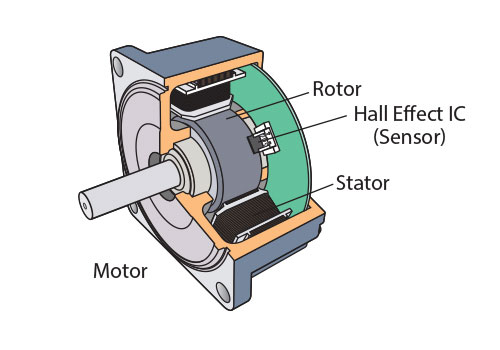

1. Rotor: The Rotor plays a pivotal role in the smooth running of BLDC motor applications. It is attached to the permanent magnets and the positions of poles may vary depending upon the number of poles used.

2. Stator: The Stator is the second major part in the making of the BLDC motor. In most BLDC motor applications, three stators are used in the shape of “Y”. It is similar to the ones used in induction motors.

3. Hall Sensors: Once the rotor and stator are in their position, It’s essential to make sure that the rotor’s position is well-known to the driver and that the windings of the stator are charged enough to run the motor.

Hall sensors play the role of detecting the position of the rotor. They are placed in the stator so that they can continuously supervise the rotor’s dynamic position and convert it into electrical signals.

How does the BLDC motor work?

Did you think the BLDC motor came from some other planet and would work differently? Well, no. The working principle of BLDC motors is similar to the Brushed DC motors. According to the Lorentz law, whenever the current-carrying conductor is placed in a magnetic field, it experiences a force. Consequently, magnets experience an equal and opposite force. In BLDC motors, the current-carrying conductor or armature is stationary and the magnet is moving.

When the stator coil gets energy from a direct source, it becomes an electromagnet and starts producing its uniform field. Though this motor is DC, the unusual force and energy allow it to generate AC which is powerful in comparison to DC motors. Then, the electromagnet stator comes into contact with the permanent magnet rotor, hence the rotor rotates.

Advantages of Brushless DC Motor

Brushless DC (BLDC) motors offer several advantages that have revolutionised various industries, from automotive to aerospace and robotics. These advanced motors, known for their efficiency, reliability, and precise control, have become the preferred choice for applications demanding high performance and energy savings.

1. Low Maintenance: There is no need for much maintenance as it is brushless.

2. Ratio: It has a high torque-to-weight ratio compared to Brushed DC motors.

3. High speed: As we have already mentioned above, it is known for its high speed and in addition, it generates less electric noise.

4. Reduced size: Its size is reduced along with superior thermal characteristics.

5. Longer lifespan: BLDC motors have a longer lifetime as there is no problem with brush and commutator erosion.

6. Noise reduction: Lower noise due to the absence of brushes.

7. Electromagnetic interference: Decrease in Electromagnetic interference.

8. There are no commutator-associated problems.

Disadvantages of Brushless DC Motor

Nothing is perfect! Everything has its two faces – positive and negative. No matter how good or advantageous BLDC is, there have to be some drawbacks to it. So, let’s have a keen look at its disadvantages which don’t necessarily make it useless or any less better because BLDC motor applications are enough to neautralise them.

1. Costly: These motors are expensive given the fact that it has a much longer list of advantages than the limitations.

2. Complex maintenance: Though it requires low maintenance, it has to be specific which makes it less accessible to the average users who are not equipped with specialised knowledge.

3. Requirement of spare sensors: BLDC motors require additional sensors to make sure that the rotor is positioned precisely.

4. Need to cool down: Sometimes, brushless DC motors may need to be cooled down if the body gets overheated during high-power operations.

5. Requirement of electronic controller: BLDC motors require spare controllers to function efficiently. It is one of the main reasons it is expensive.

Summary

Brushless DC (BLDC) motors have become integral in various industries due to their efficiency and reliability. Unlike brushed DC motors, BLDC motors feature a rotor with magnets, eliminating brushes and external connections for enhanced performance. They utilise closed-loop control systems with hall sensors to monitor rotor position, ensuring precise control and optimal operation.

One of the key advantages of BLDC motors is their low maintenance requirement, attributed to the absence of brushes that can wear out over time. Additionally, BLDC motors offer a high torque-to-weight ratio, making them suitable for applications requiring powerful yet compact motors. Their longer lifetime reduced noise output, and superior efficiency further contribute to their appeal in diverse applications.

Despite these advantages, BLDC motors have some drawbacks, including higher initial costs and the need for specialised maintenance and additional sensors. However, the benefits they offer, such as reduced size, longer lifespan, and decreased electromagnetic interference, make them a preferred choice for applications demanding high performance and reliability.

BLDC motors find extensive applications in consumer electronics like computer hard drives, transportation systems including electric vehicles and hybrid vehicles, industrial machinery such as CNC tools and robots, and various other fields. Their ability to deliver consistent performance, precise control, and energy efficiency has made them a cornerstone of modern technological advancements, driving innovation and progress across industries.